PLACON NEWS

EcoStar PET Recycling and Extrusion Facility Featured in March’s Plastics Technology Magazine

March 21st, 2013

As one of the first thermoformers to build its own in-house recycling facility to process and extrude sheet from post-consumer bottles and thermoforms, EcoStar is one of the largest operations of its kind in the Midwest US.

Pushing beyond industry standards in packaging design and sustainability is nothing new for Placon, a leader in the design and manufacture of custom and stock thermoformed products as well as recycled PET extruded sheet. In this month’s Plastics Technology feature article “Sheet Operation Closes Loop on PET Recycling”, the magazine focuses on parent company, Placon’s EcoStar recycling and extrusion process.

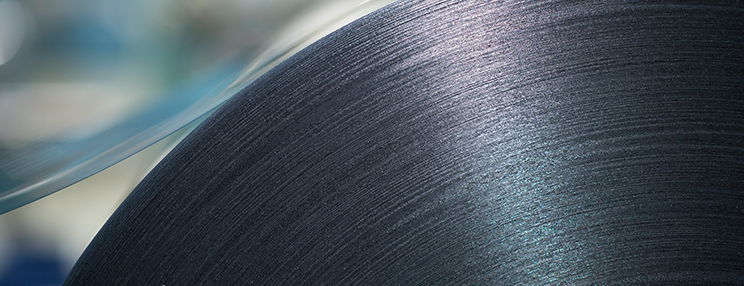

As one of the first thermoformers to build its own in-house recycling facility to process and extrude sheet from post-consumer bottles and thermoforms, EcoStar is one of the largest operations of its kind in the Midwest US. With a vision to “close the loop”, the EcoStar facility reprocesses up to 120,000 lbs/day of post-consumer recycled PET bottles and thermoforms which are then extruded into food and non-food grade PET sheet for packaging and other applications.

To read the entire article, click here.

For more information about EcoStar PET rollstock materials, please call 800.480.8940 or email info@ecostarplastics.com.

ABOUT ECOSTAR

EcoStar is a North American recycler and extruder of high-clarity, thin-gauge rigid PET rollstock for thermoformed food, retail and non-sterile medical packaging applications. One of the largest in the Midwest, the WI-based EcoStar facility reclaims and recycles over 1 billion curbside collected plastic bottles and thermoforms a year, extruding them into ultra clear, sustainable PET rollstock that is 100% recyclable. For more information, visit www.ecostarplastics.com.